Introduction:

Tablets and

capsules are like other dosage forms which are subjected to those pharmacopoeial

standards which deals with “added substances” respective to their toxicity,

interference with analytical methods, etc. However, some procedures are apply

specifically to tablets and capsules which are designed not only to ensure that

the tablet or capsules achieve its full pharmacological actions, but also to

determine the uniformity of the physical properties of the official

tablet/capsule, irrespective of the manufacturer.

Standards can be

found in the British Pharmacopoeias and United Pharmacopoeia which include the

uniformity of diameter, uniformity of weight, content of active ingredients,

uniformity of content, disintegration and dissolution. Besides, there are a few

number of quality control which are widely applied but not defined in the

pharmacopoeias such as thickness, hardness and friability.

The experiments

below demonstrate the application of a number of selected physical and dosage

performance test on samples of commercially available tablets and capsules.

Official pharmacopoeias are required to be refer for more detailed description

of other test which is not carried out in this practical session.

Procedure:

Experiment

1- Uniformity of diameter, thickness and hardness

1. 10

tablets were selected and test was carried out for uniformity of diameter,

thickness and hardness using the Tablet Testing Instrument ( PHARMATEST PTB

311)

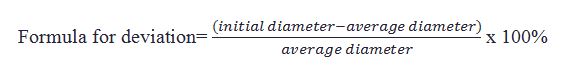

2. The

deviation of individual unit were measured. The mean diameter shall not exceed

±5% for tablet with diameter less than 12.5 and 3± for diameter of 12.5mm or

more.

Experiment

2- Tablet friability

1. 10

Tablets were selected and weighted.

2. All

tablets were placed into the drum of tablet abration and friability tester. The

rate of rotation were set at 100rpm, time to 10minutes and operation were

start.

3. At

the end of operation, all tablets were removed and the tablets were ensured to

be free from dust and powder by using a brush. The tablets were reweigh. The

percentage loss of weight were determine.

4. The

compressed tablet weight should not loss more than 1% of its initial weight.

Friability tester

Experiment

3- Uniformity of weight of tablets and capsule

Tablet

1. 20

tablets were selected randomly and weighted. The average weight were determine.

2. Tablets

were weigh individually. Each tablet’s percentage deviation of it’s weight from

the average weight were measured.

3. The

deviation of individual weight from the average weight should not exceed the

limits given below.

Average weight of

tablet

|

Deviation (%)

|

Number of Tablets

|

Less than 80mg

|

±10.0

±20.0

|

Minimum 18

Maximum 2

|

80mg to 250mg

|

±7.5

±15.0

|

Minimum 18

Maximum 2

|

More than 250 mg

|

±5.0

±10.0

|

Minimum 18

Maximum 2

|

Capsules

1. 20

Capsules were selected randomly

2. One

capsule were weighed. The capsule was open and the contents were removed as

completely as possible. The emptied shell were weighed and the net weight of

the content were determined by subtracting the weight if shells from the weight

of the intact capsule.

3. The

procedure was repeated with other 19 capsules.

4. The

average net weight was determined from the sum of the individual net weights.

5. The

percentage deviation was determine from the average net weight for each

capsule. The deviation of individual net weight should not exceed the limits

given below.

Average net weight of

capsule

|

Deviation (%)

|

Number of tablets

|

Less than 300 mg

|

±10.0

±20.0

|

Minimum 18

Maximum 2

|

300mg or more

|

±7.5

±15.0

|

Minimum 18

Maximum 2

|

Experiment

4- Dosage performance tests

Disintegration

test for sugar-coated tablets

1. Apparatus

were set up for the disintegration test according to its operation manual.

2. The

temperature of the disintegration medium ( water) was ensure to be at 37±2

°C.

3. The

time was set to 60 minutes. One tablet was introduce into each tube, the disk

was added into each tube and the operation was started.

4. The

tablet was check in each tube at the end of the operation.

5. If

all the 6 tablets disintegrate in 60 minutes, the tablets will comply with the

test. If the tablet does not disintegrate, the test will be repeated using 6

new tablets but replace the medium with 0.1M hydrochloric acid. The tablets

will be comply with the test if all 6 tablets disintegrate in the acidic

medium.

Dissolution

test for tablets

1. Dissolution

vessel was fill up with buffer solution to 900 ml mark. The temperature was set

up to 37°C.

2. The

temperature of the dissolution medium were checked. The temperature was ensure

to be at 37±0.5°C.

3. One

Ibuprofen Tablet were placed into each dry basket assembly.

4. The

stirring speed was set up to 150 rpm. The basket was lower to assembly into

positon in the vessel and the operation were started.

5. After

30 minutes, 10 ml samples of dissolution medium were withdraw from each vessel

for analysis and the solution were filter using suitable filter. The sampling

was done from a point half-way between the surface of the dissolution medium

and the top of the rotating basket, and not less than 10mm from the wall of the

vessel. The volume of aliquot withdrawn for analysis were replaced with an

equal volume of the same dissolution medium.

6. A

standard solution of ibuprofen were prepared by diluting 10.0mg of ibuprofen

reference standard to 50 ml of dissolution medium.

7. 2.0ml

of sample solution and 2.0ml of standard solution were diluted to 25ml of

dissolution medium in separate volumetric flasks.

8. The

absorption of both solution were measured in a 1cm cell at a wavelength of

221nm.

9. The

percentage amount of ibuprofen dissolved was calculated using the formula

below.

At/As ·W/50·2/25·P·900·25/2·100/200

Where

At = absorbance of sample

solution

AS=

absorbance of the standard solution

W= Weight of ibuprofen reference

standard used

P = Purity of ibuprofen reference

standard

10. According

to the results above, the tablets were determined to see whether do they

complied with the requirements of the British Pharmacopoeia ( Assume Q= 75%)

Experiment

5- Content of ibuprofen( Assay)

1. 20

Ibuprofen Tablets were selected randomly. They were then weigh and powder.

2. A

quantity of powder containing 0.5 g of Ibuprofen were extracted with 20 ml

chloroform for 15 minutes and were filtered through a sintered glass crucible (

BS Porosity No.1)

3. The

residue was wash with 3·10 ml chloroform. The filtrate was gently evaporated in

a current of air. The residue is again dissolve in 100ml of ethanol (96%) which

was previously neutralised to phenolphthalein solution.

4. The

solution was titrate with 0.1M sodium hydroxide to end point with

phenolphthalein solution as the indicator. The content of ibuprofen was

calculated whereby 0.1M sodium hydroxide is equivalent to 0.02063g of C13H1802.

Results:

Experiment

1- Uniformity of diameter, thickness and hardness

Tablet

|

Thickness (mm)

|

Diameter (mm)

|

Hardness (N)

|

Deviation of diameter

(%)

|

1

|

4.02

|

12.76

|

264.74

|

0.05

|

2

|

4.21

|

12.79

|

255.87

|

0.28

|

3

|

4.18

|

12.74

|

273.05

|

0.11

|

4

|

4.00

|

12.74

|

229.27

|

0.11

|

5

|

3.98

|

12.74

|

250.52

|

0.11

|

6

|

4.02

|

12.74

|

274.52

|

0.11

|

7

|

3.96

|

12.75

|

255.50

|

0.03

|

8

|

4.01

|

12.74

|

229.46

|

0.11

|

9

|

4.09

|

12.77

|

254.77

|

0.16

|

10

|

4.10

|

12.77

|

278.23

|

0.16

|

Mean:

|

4.06

|

12.75

|

256.593

|

Discussion (Exp 1):

During tablet

manufacture, the thickness of tablets is depending on the force used to

compress the powder. The larger the force applied, the more thinner and more

compact the tablet. Meanwhile, a compact tablet takes longer time to

disintegrate, dissolve and be absorbed by our body. On the other hand, thick

tablet can break very easily and might not survive the manufacture, packaging,

transport and usage process. Therefore, a medium thickness for a tablet is

essential.

In this

experiment, tablets were tested for their thickness, diameter and hardness by

using the Tablet Testing Instrument (PHARMATEST PTB 311). The mean thickness of

tablets in this experiment is 4.06 which is a medium range for tablet’s

thickness. Besides, the mean diameter for the tablets in this experiment is

12.75mm, so the tolerance for these tablets is the deviation of individual unit

from the mean diameter should not exceed ±

3%. The table above shows that the

deviation of the individual unit does not exceed ±

3%, at most only 0.28%. Therefore, we can conclude that the tablets have uniform diameters.

Experiment

2- Tablet friability

Discussion (Exp 2):

A test on table

friability was conducted. Friability is the tendency for a tablet to chip,

crumble or break following compression. It can be caused by a number of factors

such as poor tablet design, insufficient binder, etc. Tablets need to be hard

enough so that they do not break easily in the bottle but friable enough to

disintegrate in the gastrointestinal tract. Based on the experiment, the tablet

only loss 0.9% of its initial weight after the test( by using a friabilator).

This shows that the friability of the tablets are acceptable.

Experiment

3- Uniformity of weight of tablets and capsule

Capsules

Discussion (Exp 3-Capsules):

As the average

net weight of capsules is 0.302g or 302mg which is more than 300mg, we use the

deviation ±7.5% (Minimum 18) and ±15.0% (Maximum 2) as standard.

None of the

capsules exceed ±7.5%, the magnitude of highest percentage deviation is 2.52%

while the lowest percentage deviation is 0.07%.

The capsules

pass the test.

Tablets

Discussion (Exp 3-Tablets):

As the average net weight of these 20 tablets is 0.5723g or

572.3mg which is more than 300mg, we use ±7.5%

(Minimum 18) and ±15.0 (Maximum 2) as standard.

None of the

tablet exceeds the range of ±7.5%. The magnitude of highest percentage

deviation is 4.11% while the lowest is ±0.12%.

Thus, those

tablets pass the test.

Experiment

4- Dosage performance tests

1. Disintegration

test for sugar-coated tablets

After an hour, all the six

sugar-coated tablets were disintegrated completely in the water, left only the

sugar coatings on the discs.

Discussion (Exp 4-Disintegration test for sugar-coated

tablets):

Disintegration test is

widely used in the evaluation of the disintegration capability of different

formulations as well as quality control of different dosage forms. In this

experiment, six sugar-coated tablets were used to determine whether the tablets

can disintegrate within the prescribed time when placed in a liquid medium that

is water under at the temperature same as our body temperature. Although the

time assigned for the experiment is an hour, through observation, all the

tablets had disintegrated when the time passed 30 minutes, this shows that the

tablets have high disintegration capability. Water is used as the liquid medium

because it is closely resemble to the environment in our digestive track in

which high proportion is made up of water. However, the pH of the stomach as

well as small intestine have not yet take in to account. The high

disintegration capability of the tablets may be due to the appropriate

proportion of disintegrate agent like starch and microcrystalline cellulose in

the tablets. The disintegrate agents absorb the water in the surrounding and

expand, hence push the powder outwards, help the disintegration of the tablets.

2. Dissolution

test for tablets

Result

Absorbance

of sample solution, At

|

0.654

|

Absorbance

of standard solution, As

|

3.612

|

% amount of

ibuprofen dissolved

= At/As × W/50 × 2/25 × P × 900 × 25/2 × 100/200

= 0.654/3.612 × 10mg/50 × 2/25 × 0.98 × 900 × 25/2 × 100/200

= 15.97%

Discussion

(Exp4-Dissolution test for tablets):

After

conducting the experiment, we obtain only 15.97% dissolved ibuprofen. This

shows that the ibuprofen tablet is not comply with the requirement of British

Pharmacopoeia, as the acceptance criteria is not less than (Q + 5)%, where Q =

75%. 15.97% dissolved ibuprofen shows that there are too little ibuprofen

dissolved in the dissolution medium due to some error occurs.

One

of the errors is that the sample solution and standard solution of the

ibuprofen prepared in the volumetric flask are not shaked well before measuring

the absorbance of both solutions. In addition to that, the physicochemical

properties of the ibuprofen may be altered due to instability. Change in

physicochemical properties will directly affect the solubility of ibuprofen.

While

conducting the experiment of dissolution test, many precaution steps need to be

taken. Firstly, the temperature of dissolution medium have to be at 37 ± 0.5°C, as this may affect the amount

of dissolved ibuprofen. Besides, we must be careful while diluting the

ibuprofen solution. Make sure the solution accurately reach the calibration mark

of the volumetric flask. In addition to that, parallax error must be avoided as

it will affect the final result. Make sure the eyes are always perpendicular to

the plane of measuring cylinder and syringe, and the calibration mark of the

volumetric flask.

Conclusion:

Experiment 1 - Tablets in this experiment have diameter larger than 12.55mm, deviations of individual unit from mean diameter of these tablets do not exceed ± 3%. Hence, we can conclude that the tablets passed the test the uniformity test.

Experiment 2 - The tablets only loss 0.9% of its initial weight after the test by using a friabilator, this shows that the friability of the tablets can be accepted.

Experiment 3 - The consistency and accuracy of content in a tablet or capsule can be tested by weighing the individual weight of sample tablet or capsule and compare with the average weight of sample tablet or capsule.

Experiment 4 - The amount

of active compound in the tablets must be accurate and consistent in order to

have the therapeutic effect on the body. Tests are carried out to determine the

amount of active compounds in the tablets before the batch of tablets being

dispensed. If the average amount of active compound is not within the range,

then the tablets cannot be dispensed.

References:

- United States Pharmacopeia, General Chapter. Disintegration (701).

- http://www.who.int/medicines/publications/pharmacopoeia/TabletFriability_QAS11-414_FINAL_MODIFIED_March2012.pdf

- https://www.academia.edu/4110379/Quality_Controlling_of_Tablets

Questions:

1. What

are the objectives of the tests for uniformity of diameter and uniformity of

content?

The objectives

of the test for uniformity of diameter is to increase the patient compliances

by increasing by improving the product appearance and to prevent confusion

among patients towards the dosage of the medications. On the other hand, the

objectives if the uniformity of content is to ensure that no overdose cases

occur in patient because non-uniform amount of active ingredients in the

capsule or tablets might lead to lethal effects towards patients.

2. States

the types of tablets and capsules that must be tested for uniformity of

diameter and uniformity of content.

Test for uniformity of

diameter involve uncoated and coated tablets but does not apply on enteric

tablets, film-coated tablets and sugar coated tablets. However, it involve all

tablets in uniformity of content test.

3. Give

reasons for the non-compliance to test for uniformity of weight.

The reasons where

non-compliance occur while testing the uniformity of weight is due to uneven

feeding of granules into the die. Another reasons might be due to irregular

movement of the lower punch that cause variation in capacity die space.

4. Why

is dissolution test suitable to be used for batch to batch quality control?

After oral

administration, drug absorption depends on the release of the drug from the

product, dissolution rate under physiological conditions and the permeability

across the gastrointestinal tract. Therefore, dissolution rate of tablets and

capsules are important as it will affect their performance. Therefore, in vitro

dissolution test are important for immediate release solid oral dosage forms (

eg: tablets and capsule) which is used to assess the batch to batch drug

quality control.

5. Describe

other apparatus that you can use to conduct dissolution test apart from the one

found in the laboratory.

Another dissolution

test for Ibuprofen can be conducted by Sotax CE70 flow through cell. 2 cells

with different diameter were used, which is 12mm and 26mm respectively. The

small cell was packed with a rubin bead at the bottom, a meatal filter and a

glass fiber on which 4 grams of glass beads and drug was placed. In the top pf

the cell, a glass fiber filter was place to prevent particles to leave the cell

with the eluat. The cell with larger

diameter was packed in the same way, just that small cell lack of the lower

metal-glass fiber filter. The purpose of glass bead was to produce a laminar

flow of the medium. The flow of medium was either 8 or 16 ml/min. All the

experiment were conducted at the temperature of 37°C.